Enhancing Panel Finishing with PVC Edge Banding Strips: A Comprehensive Guide

When it comes to panel finishing in the construction and decorative materials sector, PVC edge banding strips have become an indispensable component. These strips are designed to cover the exposed edges of various types of panels, providing not only a polished look but also enhancing durability and resistance to wear and tear. PVC edge banding strips are made from polyvinyl chloride, a versatile p

Release time:

18 Jan,2026

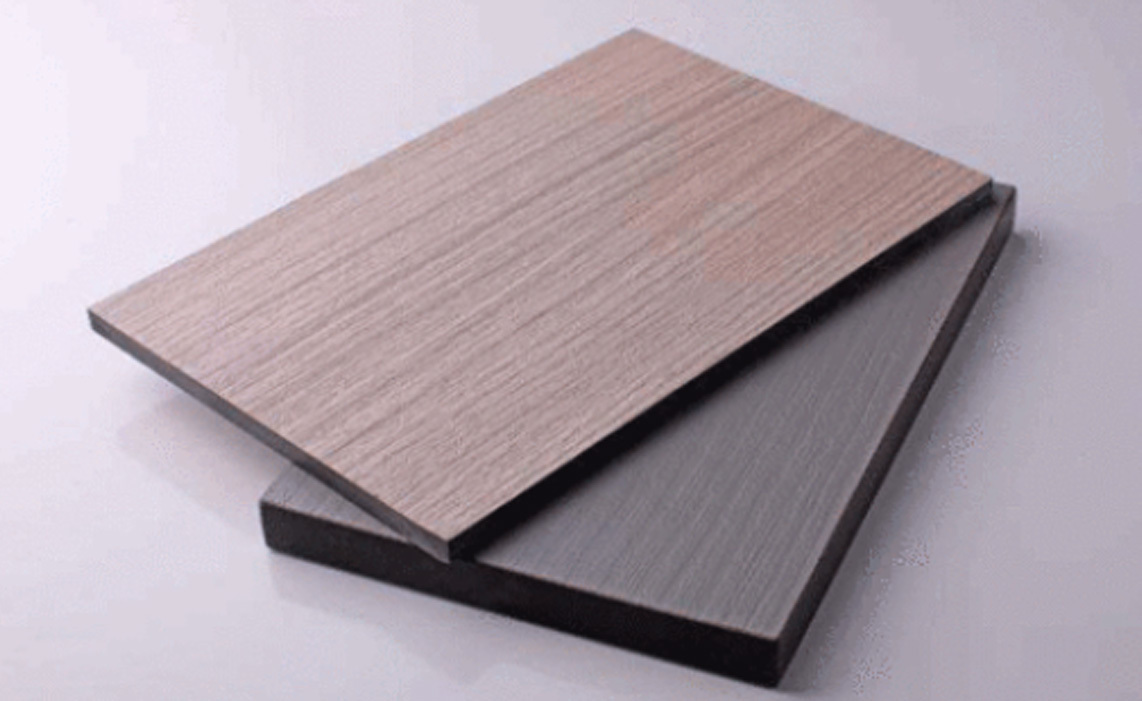

PVC edge banding strips are made from polyvinyl chloride, a versatile plastic known for its strength and flexibility. One of the most significant advantages of using PVC for edge banding is its ability to withstand moisture, making it an ideal choice for kitchens and bathrooms where humidity is a concern. Furthermore, PVC strips are available in a wide range of colors and textures, allowing for seamless integration with different panel finishes, including MDF, particleboard, and plywood.

One of the primary benefits of using PVC edge banding strips is their contribution to the longevity of the panels. When edges are left exposed, they are vulnerable to chipping and peeling, which can compromise the structural integrity of the panel. By applying PVC edge banding, you create a protective barrier that also enhances the overall appearance of the finished product. This can be particularly important in high-traffic areas where surfaces are subjected to frequent use.

In addition to their protective qualities, PVC edge banding strips offer an easy and cost-effective means of achieving a professional-grade finish. They can be applied using various methods, including hot melt adhesives and pressure-sensitive adhesives. This versatility means that whether you are a seasoned professional or a DIY enthusiast, you can achieve a high-quality finish with relative ease.

For optimal results, it’s essential to consider the thickness and width of the PVC edge banding strips in relation to the panels being used. Selecting the appropriate dimensions will ensure better adhesion and a more seamless appearance. Additionally, proper surface preparation is crucial; panels should be clean and free of dust or grease to facilitate strong bonding.

Another important consideration is the cutting and trimming of the edge banding. Using specialized tools such as edge banding trimmers can help achieve a clean, finished look. After installation, it’s advisable to sand the edges lightly to remove any excess adhesive and to create a smooth transition between the edge banding and the panel surface.

In conclusion, PVC edge banding strips are a practical and effective solution for enhancing panel finishes in various applications. Their ability to provide aesthetic appeal while protecting against damage makes them a valuable addition to any construction or decorative project. By understanding their benefits and best practices for installation, you can ensure that your panel finishes look professional and last for years to come.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible