The Environmental Impact of Using Laminated Boards in Construction: A Comprehensive Analysis

The Environmental Impact of Using Laminated Boards in Construction Table of Contents 1. Introduction 2. Understanding Laminated Boards 3. Sustainability of Laminated Boards 4. Environmental Benefits of Laminated Boards 5. Potential Environmental Concerns 6. Lifecycle Analysis of Laminated Boards 7. Case Studies on Laminated Boards 8. Future Prospects and Innovation

Release time:

19 Jan,2026

The Environmental Impact of Using Laminated Boards in Construction

Table of Contents

- 1. Introduction

- 2. Understanding Laminated Boards

- 3. Sustainability of Laminated Boards

- 4. Environmental Benefits of Laminated Boards

- 5. Potential Environmental Concerns

- 6. Lifecycle Analysis of Laminated Boards

- 7. Case Studies on Laminated Boards

- 8. Future Prospects and Innovations

- 9. FAQs

- 10. Conclusion

1. Introduction

The construction industry has witnessed significant advancements in materials technology, with laminated boards emerging as a popular choice for builders and architects alike. Understanding the **environmental impact of laminated boards** is crucial, especially as the demand for sustainable building solutions continues to rise. This article will explore the various facets of laminated boards, from their composition and manufacturing processes to their environmental benefits and potential drawbacks.

2. Understanding Laminated Boards

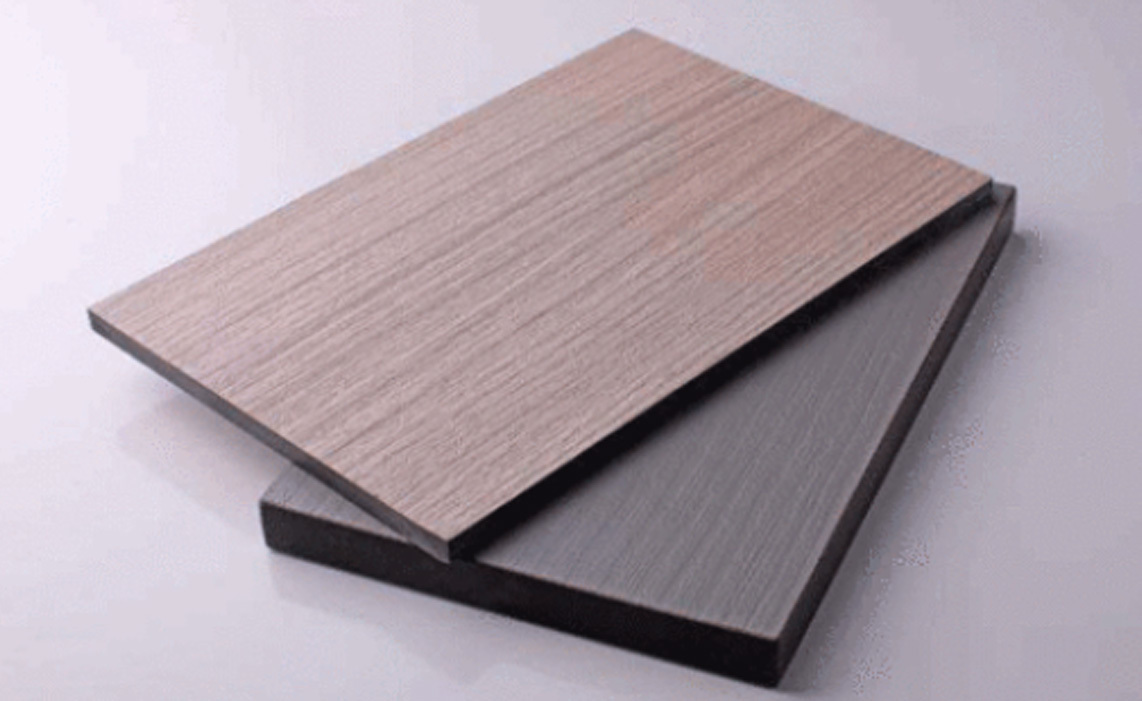

Laminated boards are engineered wood products created by bonding multiple layers of wood veneer or strands together with adhesives. This process results in a material that is not only strong and durable but also versatile for various construction applications. Common types of laminated boards include laminated veneer lumber (LVL), laminated strand lumber (LSL), and cross-laminated timber (CLT). Each type serves distinct purposes, from structural support to aesthetic finishes.

2.1 Manufacturing Process of Laminated Boards

The manufacturing of laminated boards involves several stages:

1. **Wood Selection**: High-quality timber is selected based on specific standards.

2. **Drying**: The wood is dried to reduce moisture content, ensuring optimal bonding.

3. **Lamination**: Layers of wood are bonded together using strong adhesives, often under high pressure and temperature.

4. **Finishing**: The boards may undergo additional processes such as sanding or coating for enhanced durability and appearance.

This careful manufacturing process is essential for achieving the desired strength and performance characteristics of laminated boards.

3. Sustainability of Laminated Boards

The sustainability of laminated boards hinges on several factors, including the sources of raw materials and the environmental practices of manufacturers. When sourced from responsibly managed forests, laminated boards can be a sustainable option.

3.1 Certification Standards

Many laminated boards carry certifications such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC). These certifications ensure that the wood is harvested sustainably, supporting responsible forestry practices and promoting biodiversity.

4. Environmental Benefits of Laminated Boards

Laminated boards offer numerous environmental benefits that contribute to their increasing popularity in construction.

4.1 Reduced Waste

The production of laminated boards often utilizes smaller trees and wood residues that might otherwise go to waste. This efficient use of resources helps minimize deforestation and supports sustainable forest management.

4.2 Energy Efficiency

Laminated boards provide excellent insulation properties, which can lead to energy savings in buildings. Well-insulated structures require less energy for heating and cooling, resulting in lower greenhouse gas emissions over their lifecycle.

4.3 Carbon Sequestration

Wood, including that used to produce laminated boards, stores carbon dioxide. As trees grow, they absorb CO2 from the atmosphere, effectively mitigating climate change. Utilizing wood products in construction can contribute to carbon sequestration efforts.

5. Potential Environmental Concerns

Despite their benefits, there are potential environmental concerns associated with laminated boards that warrant discussion.

5.1 Adhesives and VOC Emissions

Many adhesives used in the lamination process contain volatile organic compounds (VOCs), which can have adverse effects on indoor air quality. Manufacturers are increasingly moving towards low-VOC or no-VOC adhesives to address this concern, but it's crucial for builders to be aware of the products they choose.

5.2 Resource Depletion

While laminated boards can be a sustainable choice, over-reliance on wood resources can lead to deforestation and habitat loss if not managed responsibly. Ensuring that laminated boards are sourced from certified, sustainable forests is essential to mitigating this risk.

6. Lifecycle Analysis of Laminated Boards

A comprehensive lifecycle analysis (LCA) assesses the environmental impacts of laminated boards from production to disposal. This analysis considers various stages, including raw material extraction, manufacturing, transportation, use, and end-of-life disposal.

6.1 Environmental Impact Assessment

The LCA of laminated boards typically reveals that they have a lower environmental impact compared to traditional solid wood products. The efficiency of the lamination process and the ability to use less desirable wood species contribute to this reduced impact.

6.2 End-of-Life Considerations

At the end of their lifecycle, laminated boards can be repurposed, recycled, or even used for energy production through biomass methods. This flexibility helps minimize waste and promotes a circular economy.

7. Case Studies on Laminated Boards

Examining real-world applications of laminated boards provides valuable insights into their environmental performance.

7.1 Successful Projects

Several notable construction projects have successfully implemented laminated boards, showcasing their benefits:

- **The T3 Building**: Located in Minneapolis, this office building utilizes CLT, demonstrating the material's strength and sustainability.

- **The Brock Commons Tallwood House**: This student residence at the University of British Columbia is one of the tallest wooden buildings in the world, highlighting the potential for laminated boards in high-rise construction.

These projects not only emphasize the structural capabilities of laminated boards but also their positive environmental impacts.

8. Future Prospects and Innovations

The future of laminated boards in construction looks promising, with ongoing innovations aimed at enhancing their sustainability.

8.1 Advancements in Materials

Researchers are exploring new materials and adhesives that further reduce environmental impacts while maintaining performance. Innovations in bio-based adhesives and treatments can enhance the sustainability of laminated boards.

8.2 Increased Adoption in Green Building

As the push for eco-friendly construction continues, laminated boards are likely to see increased adoption in green building practices. Their versatility and sustainability make them a viable choice for meeting stringent environmental standards.

9. FAQs

1. What are laminated boards made of?

Laminated boards are typically made from layers of wood veneer or strands bonded together using adhesives.

2. Are laminated boards eco-friendly?

Yes, when sourced from sustainably managed forests and produced using low-VOC adhesives, laminated boards can be an eco-friendly construction material.

3. How do laminated boards compare to solid wood?

Laminated boards generally have a lower environmental impact than solid wood due to their efficient use of resources and ability to utilize less desirable wood species.

4. What are the main benefits of using laminated boards in construction?

The main benefits include reduced waste, energy efficiency, carbon sequestration, and versatility in design.

5. Can laminated boards be recycled?

Yes, laminated boards can often be recycled, repurposed, or used for biomass energy production at the end of their life cycle.

10. Conclusion

The environmental impact of using laminated boards in construction presents a nuanced picture. While these materials offer significant sustainability benefits, such as reduced waste and energy efficiency, they are not without potential concerns. Understanding both the advantages and drawbacks allows architects, builders, and consumers to make informed decisions that prioritize environmental stewardship. As innovations continue to emerge, laminated boards are poised to play an even more significant role in the future of sustainable construction. Embracing these materials could help pave the way for a greener, more eco-conscious building industry.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible