A Comprehensive Guide to Laminated Boards for DIY Enthusiasts

A Comprehensive Guide to Laminated Boards for DIY Enthusiasts Table of Contents 1. What Are Laminated Boards? 2. Different Types of Laminated Boards 3. Advantages of Using Laminated Boards for DIY Projects 4. Applications of Laminated Boards in Home Decor 5. How to Choose the Right Laminated Board for Your Project 6. Step-by-Step Guide to Using Laminated Boards 7.

Release time:

31 Jan,2026

A Comprehensive Guide to Laminated Boards for DIY Enthusiasts

Table of Contents

- 1. What Are Laminated Boards?

- 2. Different Types of Laminated Boards

- 3. Advantages of Using Laminated Boards for DIY Projects

- 4. Applications of Laminated Boards in Home Decor

- 5. How to Choose the Right Laminated Board for Your Project

- 6. Step-by-Step Guide to Using Laminated Boards

- 7. Maintenance and Care for Laminated Boards

- 8. Frequently Asked Questions

1. What Are Laminated Boards?

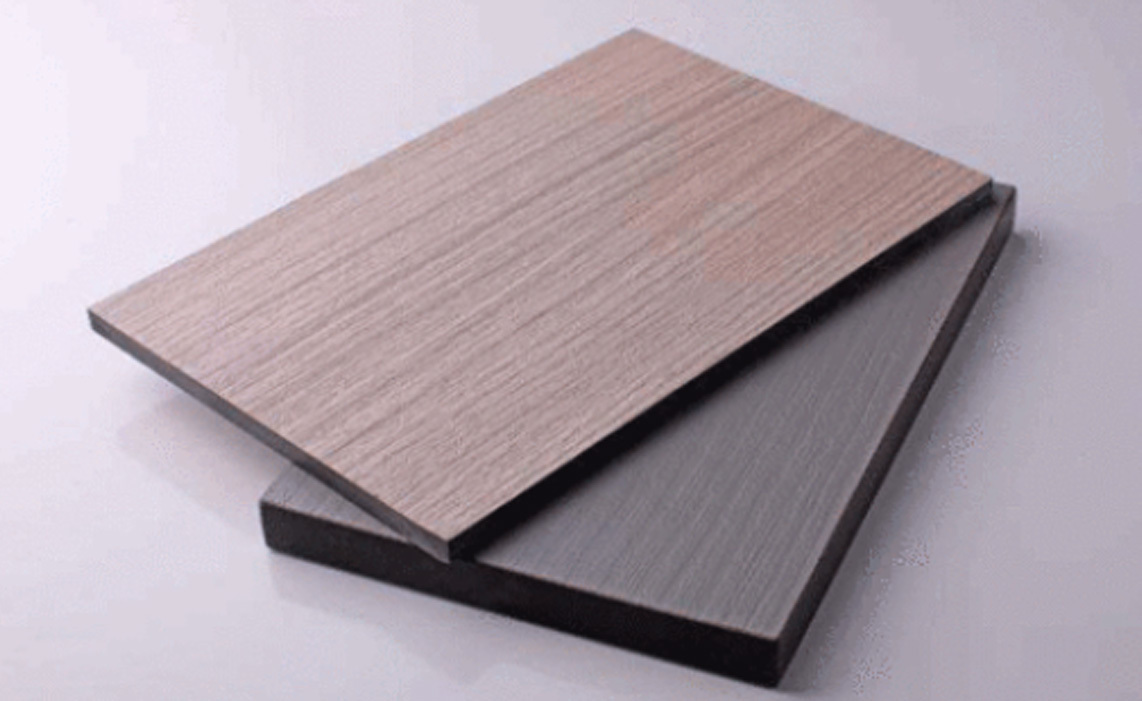

Laminated boards are engineered wood products created by bonding multiple layers of material together. These boards are typically constructed from sheets of veneer, particleboard, or MDF (medium-density fiberboard) that are fused using heat and adhesive. This process results in a product that boasts increased strength, durability, and aesthetic appeal, making laminated boards a popular choice among DIY enthusiasts.

The versatility of laminated boards allows them to be used in various applications, ranging from furniture to decorative elements in home renovations. Their availability in a wide range of colors, textures, and finishes also makes them an attractive option for any project.

2. Different Types of Laminated Boards

When selecting laminated boards, it's essential to understand the different types available. Each type has unique characteristics suited for specific applications:

2.1 High-Pressure Laminate (HPL)

High-pressure laminate is created by applying heat and pressure to multiple layers of resin-impregnated paper. HPL is renowned for its durability and resistance to scratches, impacts, and moisture, making it ideal for countertops and high-traffic areas.

2.2 Low-Pressure Laminate (LPL)

Low-pressure laminate is produced in a similar fashion to HPL but with lower pressure levels. LPL is usually thinner and less durable than HPL, making it suitable for applications like furniture and decorative panels.

2.3 Melamine-Faced Boards

Melamine-faced boards are made by applying a melamine resin over a substrate, typically particleboard or MDF. These boards offer a wide range of colors and finishes, making them a favorite for cabinetry and shelving projects.

2.4 Veneered Boards

Veneered boards feature a thin layer of real wood veneer bonded to a substrate. This option provides the natural beauty of wood while maintaining the cost-effectiveness and stability of engineered materials.

3. Advantages of Using Laminated Boards for DIY Projects

Laminated boards present a multitude of benefits for DIY enthusiasts:

3.1 Cost-Effective

Compared to solid wood, laminated boards are significantly more affordable. They provide an excellent alternative for budget-conscious projects without sacrificing quality.

3.2 Durability

Laminated boards are designed to withstand wear and tear. Their resistance to scratches, moisture, and stains makes them suitable for various applications, ensuring longevity in your projects.

3.3 Easy Maintenance

Routine cleaning is simple with laminated boards. Most surfaces require just a damp cloth for cleaning, making them ideal for busy households.

3.4 Versatile Design Options

With a range of colors, patterns, and finishes available, laminated boards provide endless design possibilities, allowing DIY enthusiasts to achieve their desired aesthetic effortlessly.

3.5 Eco-Friendly Options

Many laminated boards are made from recycled materials or sustainable wood sources, making them an environmentally responsible option for your projects.

4. Applications of Laminated Boards in Home Decor

Laminated boards can be employed in various home decor applications, enhancing the functionality and beauty of your space:

4.1 Furniture Construction

Laminated boards are widely used in creating stylish furniture, including cabinets, tables, and shelves. Their lightweight nature coupled with durability makes them an excellent choice for DIY furniture projects.

4.2 Wall Paneling

Adding laminated boards to your walls can create stunning accent walls or paneling for a modern touch. Their range of finishes allows for seamless integration into any design theme.

4.3 Flooring Solutions

Some laminated boards can be used for flooring, offering a beautiful wood-like appearance without the associated costs. They can withstand foot traffic and are available in various designs and textures.

4.4 Decorative Elements

From frames to light fixtures, laminated boards can be transformed into unique decorative elements that elevate the overall aesthetic of your space.

5. How to Choose the Right Laminated Board for Your Project

Selecting the appropriate laminated board involves considering several factors to ensure you achieve the ideal outcome:

5.1 Understand Your Project Needs

Evaluate the specific requirements of your project, such as durability, finish, and aesthetic preferences.

5.2 Assess Environmental Conditions

Consider where the laminated board will be used. For areas prone to moisture, such as kitchens or bathrooms, opt for high-pressure laminates for added durability.

5.3 Check Thickness and Size

Choose the thickness and size of the laminated board based on your project specifications. Thicker boards typically offer better durability but may also be heavier.

5.4 Look for Quality Certifications

When shopping, check for certifications that indicate quality and environmental compliance, ensuring you choose a product that meets your standards.

6. Step-by-Step Guide to Using Laminated Boards

Embarking on a DIY project with laminated boards can be straightforward. Here’s a step-by-step guide to get you started:

6.1 Gather Your Tools and Materials

Before beginning, assemble all necessary tools, including a saw, drill, clamps, adhesive, and safety gear. Ensure you have the right type of laminated board for your project.

6.2 Measure and Cut

Carefully measure the areas where the laminated board will be used. Mark and cut the boards to the desired size, ensuring clean edges for a professional finish.

6.3 Prepare Your Workspace

Create a clean, organized workspace to facilitate efficient project execution. Lay down drop cloths or protective coverings to prevent damage to your surfaces.

6.4 Assemble and Secure

Following your project plan, assemble the laminated boards using appropriate adhesives or fasteners. Use clamps to hold pieces in place while the adhesive cures.

6.5 Finishing Touches

Once assembled, sand any rough edges and apply any additional finishes, such as paint or sealants, to enhance appearance and protection.

7. Maintenance and Care for Laminated Boards

Proper care for your laminated boards ensures they remain in excellent condition over time:

7.1 Regular Cleaning

Wipe down surfaces with a damp cloth and mild detergent to remove dirt and grime. Avoid abrasive cleaners that could scratch the surface.

7.2 Prevent Scratches and Damage

Use coasters and placemats to protect surfaces from heat and scratches. Avoid dragging heavy objects across the surface to prevent damage.

7.3 Addressing Stains

For stubborn stains, utilize a mixture of baking soda and water to create a paste. Gently rub the stain with the paste, then rinse with a damp cloth.

8. Frequently Asked Questions

8.1 Can laminated boards be used outdoors?

While some laminated boards are designed for outdoor use, most are not. It's crucial to choose products specifically labeled as outdoor-rated for exterior applications.

8.2 Are laminated boards waterproof?

Laminated boards are generally water-resistant but not completely waterproof. Avoid prolonged exposure to water to prevent swelling or damage.

8.3 How do I cut laminated boards without chipping?

Using a fine-toothed saw and masking tape on the cut line can minimize chipping when cutting laminated boards.

8.4 Can I paint laminated boards?

Yes, laminated boards can be painted. However, proper surface preparation, such as sanding and priming, is essential for the paint to adhere effectively.

8.5 What is the best adhesive for laminated boards?

For bonding laminated boards, PVA (polyvinyl acetate) glue is commonly recommended for its strong adhesion and ease of use.

Conclusion

Laminated boards offer undeniable benefits to DIY enthusiasts, from versatility and durability to aesthetic appeal. By understanding the various types, applications, and maintenance requirements of laminated boards, you can confidently embark on your next project. Whether creating custom furniture, stylish wall panels, or decorative elements, laminated boards are a reliable choice that can elevate your DIY endeavors. Embrace the endless possibilities that laminated boards offer to transform your creative ideas into reality.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible