A Comprehensive Guide to Selecting PVC Edge Banding Strips: Enhance Your Furniture with the Right Choice

A Comprehensive Guide to Selecting PVC Edge Banding Strips Table of Contents 1. Understanding PVC Edge Banding Strips 2. Benefits of Using PVC Edge Banding Strips 3. Types of PVC Edge Banding Strips 4. How to Select the Right PVC Edge Banding Strips 5. The Installation Process of PVC Edge Banding Strips 6. Maintenance Tips for Long-Lasting Edge Banding 7. Common Mistak

Release time:

04 Feb,2026

A Comprehensive Guide to Selecting PVC Edge Banding Strips

Table of Contents

- 1. Understanding PVC Edge Banding Strips

- 2. Benefits of Using PVC Edge Banding Strips

- 3. Types of PVC Edge Banding Strips

- 4. How to Select the Right PVC Edge Banding Strips

- 5. The Installation Process of PVC Edge Banding Strips

- 6. Maintenance Tips for Long-Lasting Edge Banding

- 7. Common Mistakes to Avoid When Choosing Edge Banding

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Understanding PVC Edge Banding Strips

PVC edge banding strips are thin strips made from polyvinyl chloride, a popular plastic material known for its durability and versatility. These strips are used to cover the exposed edges of materials like plywood, particle board, or MDF, providing a clean and finished appearance. They not only enhance the aesthetic appeal of furniture but also protect the edges from moisture, chipping, and wear.

When selecting edge banding strips, it's essential to understand their composition, as it influences their performance and longevity. PVC is favored for its excellent resistance to impact and abrasion, making it ideal for high-traffic areas in both residential and commercial spaces.

2. Benefits of Using PVC Edge Banding Strips

Choosing PVC edge banding strips offers numerous advantages:

2.1 Aesthetic Appeal

PVC edge banding comes in various colors, patterns, and finishes, allowing you to match or contrast with your furniture. This customization capability enhances the overall look and feel of your projects.

2.2 Durability and Resistance

PVC is inherently resistant to water, chemicals, and UV rays, making it suitable for various environments, including kitchens and bathrooms. Its robustness ensures that your furniture maintains its integrity over time.

2.3 Cost-Effectiveness

Compared to other edge banding materials like wood veneer or laminate, PVC is often more affordable without compromising quality. This cost-effectiveness makes it a popular choice among contractors and DIY enthusiasts alike.

2.4 Easy Maintenance

Maintaining PVC edge banding is straightforward. Regular cleaning with a damp cloth and mild detergent is typically all that’s needed to keep it looking new.

3. Types of PVC Edge Banding Strips

Understanding the different types of PVC edge banding strips available can help you make an informed decision based on your specific requirements.

3.1 Pre-glued Edge Banding

Pre-glued PVC edge banding comes with an adhesive backing, simplifying the application process. This type is ideal for DIY projects, as it can be easily applied using a household iron for heat activation.

3.2 Un-glued Edge Banding

Un-glued edge banding strips provide more flexibility in terms of adhesive choice. This option allows for a stronger bond and is usually preferred for professional installations where precision is critical.

3.3 Edgebanding with Different Thicknesses

PVC edge banding is available in various thicknesses, typically ranging from 0.4mm to 3mm. Thicker strips provide better edge protection and are recommended for high-use surfaces.

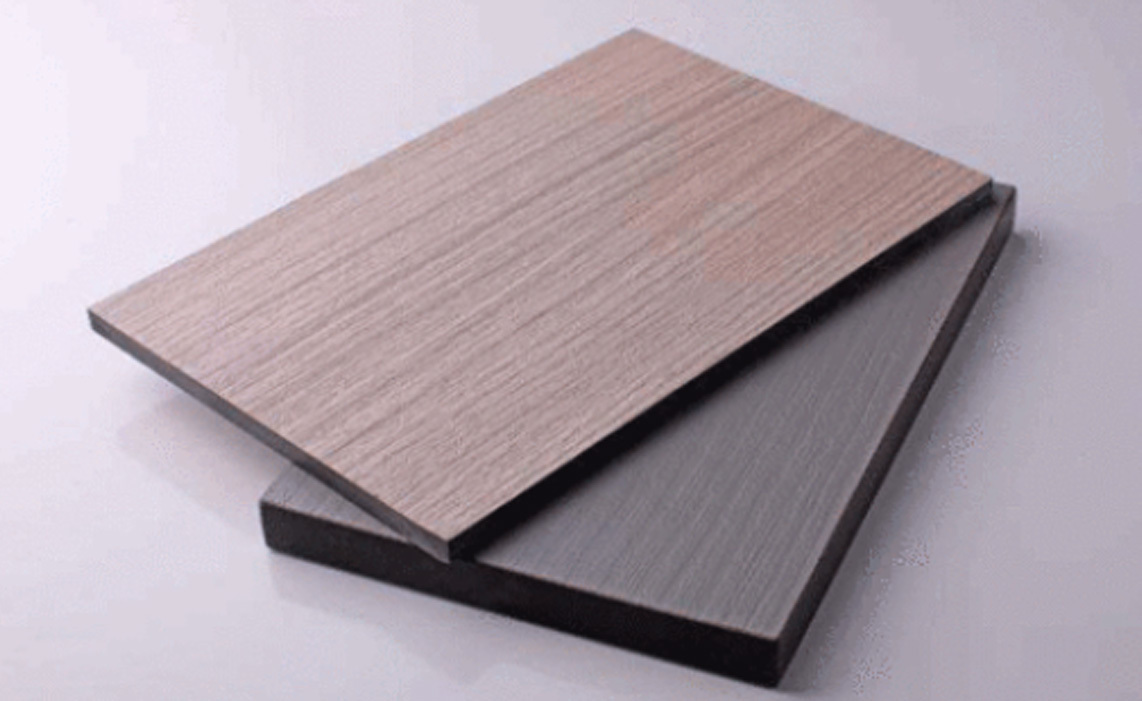

3.4 Wood Grain and Solid Colors

PVC edge banding is offered in solid colors as well as wood grain finishes. Selecting the right design can significantly enhance the visual appeal of your furniture.

4. How to Select the Right PVC Edge Banding Strips

Selecting the appropriate PVC edge banding strips requires careful consideration of several factors:

4.1 Evaluate Your Material

Check the material of the board you're covering. The thickness and type of edge banding should match the substrate for a seamless finish.

4.2 Consider the Application Area

Different environments may demand different types of PVC edge banding. For instance, areas exposed to moisture, like kitchens, should prioritize moisture-resistant options.

4.3 Match Colors and Textures

To achieve a cohesive look, select edge banding that complements the color and texture of the main material. This attention to detail can elevate the overall design.

4.4 Thickness Matters

Choose a thickness that matches the wear and tear expected in the finished product. Thicker edge banding provides more durability and protection.

4.5 Adhesive Considerations

Decide between pre-glued and un-glued options based on your skill level and the tools available. Pre-glued offers simplicity, while un-glued allows for more control.

5. The Installation Process of PVC Edge Banding Strips

Proper installation is crucial for achieving a professional finish. Here’s a step-by-step guide:

5.1 Gather Your Materials

You will need PVC edge banding strips, a utility knife, an iron (if using pre-glued), an adhesive (if using un-glued), and a scraper or roller for smoothing.

5.2 Cut the Edge Banding to Size

Measure the edges of the material to be banded and cut the strips slightly longer than needed.

5.3 Apply the Edge Banding

For pre-glued banding, align the strip over the edge and apply heat with the iron, pressing down firmly. For un-glued, apply the adhesive to the edge and position the banding accordingly.

5.4 Trim Excess Banding

Once adhered, use a utility knife to trim any excess banding from the edges for a clean finish.

5.5 Final Touches

Use a scraper or roller to ensure the banding is securely attached and smooth out any bubbles or imperfections.

6. Maintenance Tips for Long-Lasting Edge Banding

Proper care can extend the life of your PVC edge banding significantly. Here are some maintenance tips:

6.1 Regular Cleaning

Use a soft cloth and a mild detergent to wipe down the banding regularly, keeping it free from dust and grime.

6.2 Avoid Harsh Chemicals

Steer clear of abrasive cleaners or solvents that can damage the surface of the PVC.

6.3 Inspect for Damage

Regularly check for any wear or peeling. If damage occurs, address it promptly to prevent further issues.

7. Common Mistakes to Avoid When Choosing Edge Banding

When selecting and installing PVC edge banding, avoid these common pitfalls:

7.1 Ignoring Compatibility

Ensure that the edge banding is compatible with the board material in terms of thickness and type.

7.2 Overlooking Adhesive Quality

Using low-quality adhesives can lead to poor bonding. Always choose reliable products for better results.

7.3 Skipping Measurements

Accurate measurements are critical. Skipping this step can lead to wasted materials and an unprofessional finish.

7.4 Neglecting Environmental Factors

Consider the environment in which the finished product will be used when selecting edge banding materials.

8. Frequently Asked Questions (FAQs)

8.1 What is PVC edge banding used for?

PVC edge banding is primarily used to cover the exposed edges of wood-based panels, providing a finished look and protection against damage.

8.2 How do I apply PVC edge banding?

You can apply PVC edge banding using heat (for pre-glued strips) or adhesive (for un-glued strips) and a utility knife for trimming.

8.3 Can PVC edge banding be painted?

While PVC can be painted, it is usually unnecessary due to the variety of colors available. If desired, use a primer designed for plastics.

8.4 How do I remove PVC edge banding?

To remove edge banding, gently heat the adhesive to loosen it, then carefully peel off the banding.

8.5 Is PVC edge banding eco-friendly?

PVC is not biodegradable, but many manufacturers are working to develop more sustainable options. Always check for eco-friendly certifications when available.

9. Conclusion

Selecting the right PVC edge banding strips is essential for enhancing the durability and aesthetic appeal of your furniture. By understanding the types available, the benefits they offer, and following proper installation and maintenance techniques, you can ensure a professional finish that stands the test of time. With this comprehensive guide, you are now equipped to make informed decisions that will elevate your craftsmanship and lead to impressive results. Whether you are a professional contractor or a DIY enthusiast, the right edge banding can make a significant difference in your projects.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible