The Comprehensive Guide to the Pros and Cons of Using PVC Edge Banding in Commercial Spaces

The Pros and Cons of Using PVC Edge Banding in Commercial Spaces Introduction to PVC Edge Banding PVC (Polyvinyl Chloride) edge banding has become a popular choice in the world of commercial interiors. It serves to cover the exposed edges of particle board, MDF, and plywood materials, providing a finished look while enhancing durability. This versatile material is particularly favored for its cost

Release time:

06 Feb,2026

The Pros and Cons of Using PVC Edge Banding in Commercial Spaces

Introduction to PVC Edge Banding

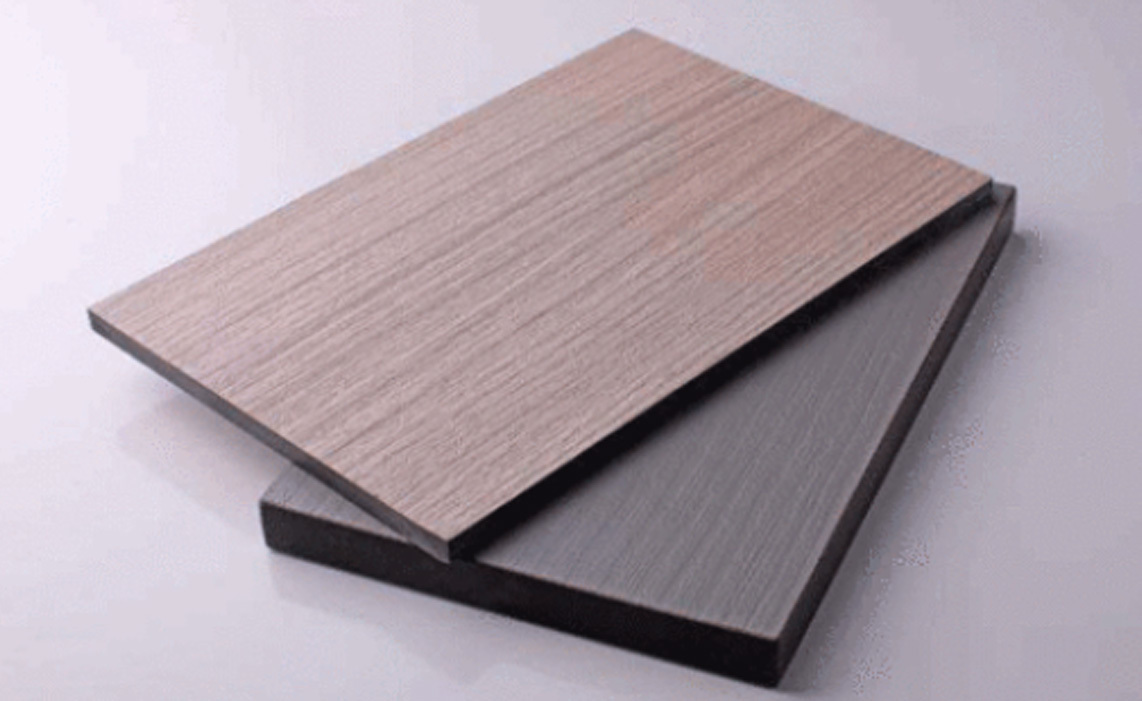

PVC (Polyvinyl Chloride) edge banding has become a popular choice in the world of commercial interiors. It serves to cover the exposed edges of particle board, MDF, and plywood materials, providing a finished look while enhancing durability. This versatile material is particularly favored for its cost-effectiveness and aesthetic appeal. In this guide, we will explore the numerous **pros and cons** of using PVC edge banding, allowing you to make an informed decision for your commercial space.

Understanding the Applications of PVC Edge Banding

PVC edge banding finds its way into a variety of commercial applications, particularly in environments demanding durability and style. Here are several areas where PVC edge banding shines:

1. Furniture Manufacturing

In furniture manufacturing, PVC edge banding is widely used to finish edges on cabinets, tables, and desks. It not only protects edges from wear and tear but also adds a polished aesthetic.

2. Retail Spaces

Retail environments often utilize PVC edge banding to give displays and shelving a sleek, professional appearance. Its variety of colors and finishes allows for seamless integration into any design scheme.

3. Office Interiors

In office spaces, PVC edge banding is common in furniture and cabinetry. Its durability supports the demands of a busy work environment while maintaining an attractive look.

The Advantages of PVC Edge Banding

PVC edge banding offers several benefits that make it a popular choice in commercial spaces.

1. Cost-Effectiveness

One of the primary advantages of PVC edge banding is its **affordability**. Compared to wood or other high-end edge finishing materials, PVC provides a budget-friendly option without compromising on quality.

2. Durability and Resistance

PVC edge banding exhibits high durability, making it resistant to moisture, heat, and chemicals. This resistance is particularly advantageous in **commercial environments** where spills and high traffic are common.

2.1 Moisture Resistance

PVC does not absorb moisture, preventing warping or swelling that can occur with wood-based materials in humid conditions.

2.2 Scratch and Impact Resistance

The robust nature of PVC allows it to withstand scratches and impacts, prolonging the lifespan of commercial furniture.

3. Aesthetic Versatility

Available in a wide array of colors, textures, and finishes, PVC edge banding can easily complement any interior design style. Whether opting for a sleek modern look or a more traditional aesthetic, PVC edge banding offers numerous options.

4. Easy Maintenance

Cleaning PVC edge banding is hassle-free. A simple wipe with a damp cloth is usually sufficient to keep it looking pristine, which is a significant advantage in busy commercial settings.

5. Quick Installation

Installing PVC edge banding is a straightforward process, often requiring minimal tools. This quick installation can save time and labor costs, making it an efficient choice for large projects.

The Disadvantages of PVC Edge Banding

While PVC edge banding comes with many benefits, it’s essential to consider potential drawbacks.

1. Environmental Impact

PVC is derived from petroleum, which raises concerns regarding its environmental footprint. While newer manufacturing processes aim to reduce this impact, traditional PVC production still poses sustainability challenges.

2. Limited Repair Options

Once damaged, repairing PVC edge banding can be difficult. Unlike wood, which can often be sanded and refinished, scratched or chipped PVC may require a complete replacement.

3. Heat Sensitivity

Although PVC is generally durable, it can be sensitive to extreme heat. Placing hot items directly on PVC edge banding can lead to deformation or discoloration.

4. Adhesive Quality

The longevity of PVC edge banding often depends on the quality of the adhesive used during installation. Low-quality adhesives may lead to peeling or detachment over time.

Choosing the Right PVC Edge Banding for Your Project

When selecting PVC edge banding for your commercial space, several factors should be considered:

1. Thickness and Width

PVC edge banding comes in various thicknesses and widths. Choosing the appropriate dimensions based on your application will ensure a proper fit and finish.

2. Color and Texture

Select a color and texture that aligns with your design vision. A wide variety of options exist, from solid colors to wood grain finishes.

3. Quality of Material

Invest in high-quality PVC edge banding. Inferior materials may lead to a shorter lifespan and increased maintenance efforts.

4. Adhesive Considerations

Ensure that the adhesive used offers strong bonding properties. This will enhance the durability and longevity of the edge banding.

Maintenance Tips for PVC Edge Banding

To keep your PVC edge banding looking its best, follow these maintenance tips:

1. Regular Cleaning

Utilize a damp cloth and mild detergent for routine cleaning. Avoid harsh chemicals that may damage the surface.

2. Inspect for Damage

Regularly check the edge banding for signs of wear or damage. Early detection can help prevent larger issues.

3. Avoid Sharp Objects

Keep sharp objects away from PVC edge banding to prevent scratches and chips.

Conclusion

In conclusion, PVC edge banding offers a range of advantages, making it an appealing choice for commercial spaces. Its cost-effectiveness, durability, and aesthetic versatility cater to the needs of various environments. However, it is essential to weigh these benefits against potential drawbacks, such as environmental concerns and heat sensitivity. By considering the applications, advantages, and maintenance of PVC edge banding, you are better equipped to make informed decisions for your commercial projects.

FAQs About PVC Edge Banding

1. What is PVC edge banding made of?

PVC edge banding is made from polyvinyl chloride, a synthetic plastic polymer that is known for its durability and versatility.

2. Can PVC edge banding be painted?

While it is technically possible to paint PVC edge banding, it’s generally not recommended due to poor adhesion and potential peeling.

3. How is PVC edge banding applied?

PVC edge banding is typically applied using a heat-activated adhesive or a pressure-sensitive adhesive, ensuring a strong bond to the substrate.

4. Is PVC edge banding suitable for outdoor use?

PVC edge banding is primarily designed for indoor applications. While it is moisture-resistant, prolonged exposure to outdoor conditions can lead to degradation.

5. How do I remove PVC edge banding?

To remove PVC edge banding, carefully heat the adhesive with a heat gun and gently lift the banding using a putty knife.

By understanding the pros and cons associated with PVC edge banding, professionals in the fields of architecture and interior design can make better choices that enhance the aesthetic and functional qualities of commercial spaces.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible