Top Mistakes to Avoid When Working with PVC Edge Banding for Flawless Results

Top Mistakes to Avoid When Working with PVC Edge Banding Introduction to PVC Edge Banding PVC edge banding serves as a vital component in the furniture and cabinetry industry, providing a clean, finished look to raw edges of panels. While it may seem straightforward, several common mistakes can compromise both the appearance and durability of your projects. This article will guide you through the

Release time:

14 Feb,2026

Top Mistakes to Avoid When Working with PVC Edge Banding

Introduction to PVC Edge Banding

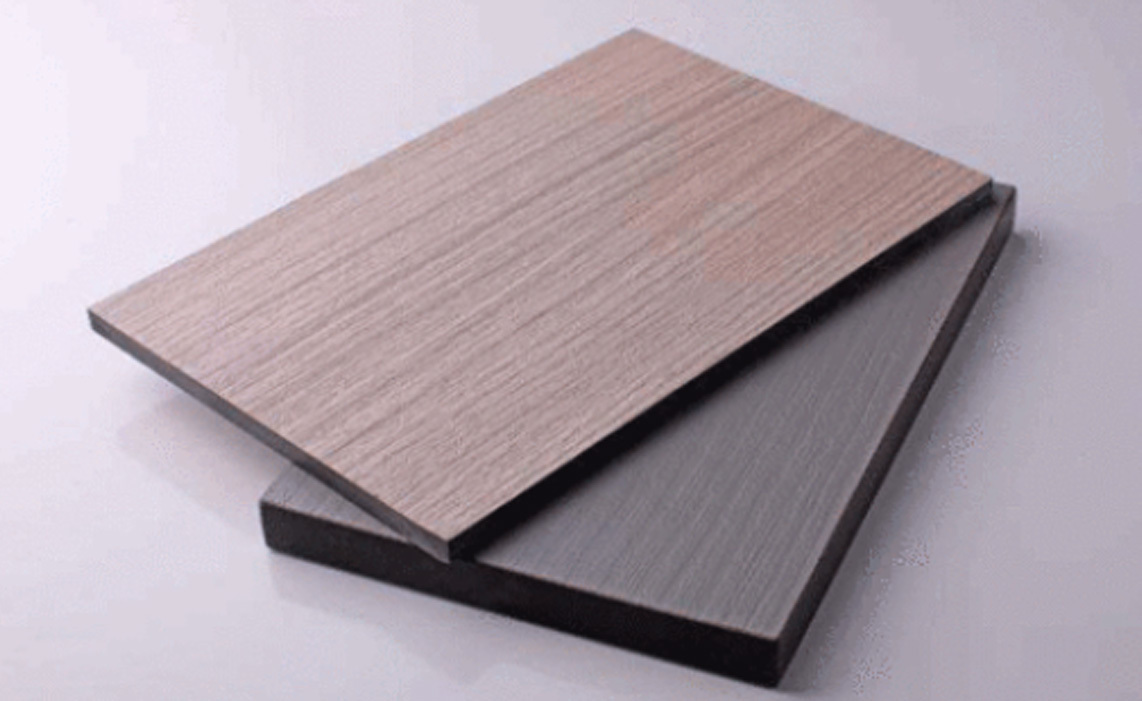

PVC edge banding serves as a vital component in the furniture and cabinetry industry, providing a clean, finished look to raw edges of panels. While it may seem straightforward, several common mistakes can compromise both the appearance and durability of your projects. This article will guide you through the top pitfalls to avoid, ensuring you achieve flawless results in your work with PVC edge banding.

Understanding the Importance of Proper Application

Before diving into the mistakes, it is essential to grasp why proper application of PVC edge banding is crucial. The edge banding not only beautifies your projects but also protects the edges from moisture, warping, and wear. A poorly applied edge band can lead to unsightly gaps, peeling, and even structural damage over time.

Common Mistakes in PVC Edge Banding Application

1. Skipping Surface Preparation

One of the most significant errors is neglecting surface preparation before applying edge banding. The substrate must be clean, dry, and free from dust or grease to ensure strong adhesion. Skipping this step can lead to bubbles and separation over time.

2. Inadequate Trimming Techniques

Trimming excess edge banding is a critical step. Many make the mistake of using dull tools or improper techniques, which can result in jagged edges or uneven finishes. Using a sharp utility knife or specialized trimmer will yield cleaner results.

3. Incorrect Adhesive Use

Utilizing the wrong adhesive for your PVC edge banding can lead to disastrous outcomes. Some might mistakenly opt for a standard wood adhesive instead of a high-temperature hot melt adhesive specifically designed for PVC. This can result in delamination or peeling when exposed to heat.

4. Ignoring Temperature and Humidity Conditions

Environmental conditions play a significant role in the application of PVC edge banding. Failing to consider factors like temperature and humidity can compromise adhesion. For optimal results, ensure that the workspace is within the recommended range for both temperature and humidity.

5. Neglecting Proper Pressure Application

After applying the adhesive, failing to apply sufficient pressure during the bonding process can lead to weak adhesion. It is vital to use a roller or a specialized pressing tool to ensure the PVC edge banding adheres properly without air pockets.

Advanced Techniques for Perfect Applications

Using the Right Tools for the Job

Investing in quality tools designed specifically for PVC edge banding can elevate your craftsmanship. Tools such as hot air guns, edge banding machines, and proper trimming devices can make a significant difference in the final outcome of your work.

Choosing the Right PVC Edge Banding Material

Not all PVC edge banding is created equal. Selecting the appropriate thickness and finish for your project is essential. Thicker materials may offer more durability but can be more challenging to work with. Consider the intended use and appearance to choose the best option.

Understanding the Different Types of PVC Edge Banding

PVC edge banding comes in various types, each suited for different applications. Understanding these can help you select the right one for your project.

Standard PVC Edge Banding

This is the most common type, suitable for general use in cabinetry and furniture. It is available in various colors and finishes to match your projects.

Flexible PVC Edge Banding

Ideal for curved surfaces, flexible PVC edge banding can be easily shaped and applied, ensuring a seamless finish on rounded edges.

High-Gloss PVC Edge Banding

For a modern look, high-gloss PVC edge banding provides a shiny finish that can enhance the aesthetic appeal of any furniture piece.

Best Practices for Seamless PVC Edge Banding Installation

Pre-Cutting and Measuring

Before application, always pre-cut the edge banding to the appropriate lengths. Accurate measuring will prevent waste and ensure a clean fit.

Using Proper Heating Techniques

When utilizing hot melt adhesive, it is crucial to maintain the right temperature. Overheating can damage the PVC, while insufficient heat may not bond effectively.

Finishing Touches for a Professional Look

After application, sanding the edges lightly with fine-grit sandpaper can enhance the finish and ensure that any irregularities are smoothed out. A final polish can give your project a professional touch.

FAQs About PVC Edge Banding

1. What is PVC edge banding, and what is it used for?

PVC edge banding is a thin strip of PVC material applied to the edges of furniture panels to provide a finished look and protection against damage.

2. How do I choose the right PVC edge banding for my project?

Consider the thickness, finish, and color that best match your project’s design and functional requirements.

3. Can I use PVC edge banding on curved surfaces?

Yes, flexible PVC edge banding is specifically designed for curved applications, allowing for seamless application on rounded edges.

4. What adhesive is best for PVC edge banding?

High-temperature hot melt adhesive is recommended for bonding PVC edge banding, as it provides a strong and lasting bond.

5. How can I fix gaps or bubbles in my PVC edge banding?

If you notice gaps or bubbles, you can carefully reheat the edge banding and press it down to eliminate air pockets or gaps.

Conclusion

By avoiding these common mistakes and utilizing best practices, you can ensure a successful application of PVC edge banding in your projects. Taking the time to prepare surfaces, select the right materials, and apply precise techniques will lead to impressive finishes and durable results. Whether you're a seasoned professional or a DIY enthusiast, mastering these aspects will enhance your skill set and elevate the quality of your work. With careful attention to detail, your projects will stand out, showcasing the beauty and functionality that PVC edge banding can offer.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible