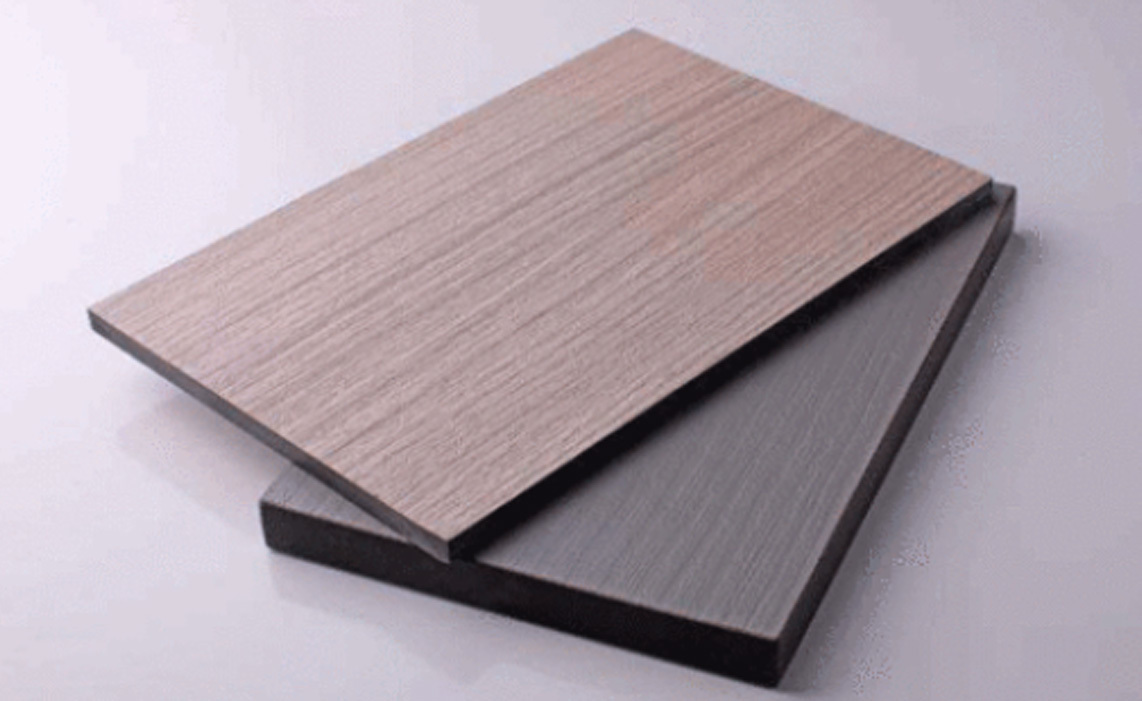

Impregnated Paper: Enhanced Strength and Versatility for Industrial Applications

Impregnated paper is treated with resins to improve strength, durability, and resistance to heat, moisture, and chemicals.

Release time:

03 Feb,2026

Impregnated paper is a type of paper that has been treated with chemical resins or other additives to improve its physical, mechanical, and chemical properties. Unlike regular paper, which is primarily composed of cellulose fibers, impregnated paper undergoes a treatment process where it is saturated or coated with resins such as phenolic, melamine, or epoxy. This process significantly enhances the paper’s strength, durability, moisture resistance, electrical insulation, and thermal stability, making it suitable for demanding industrial applications.

Manufacturing Process

The production of impregnated paper involves several key steps. First, high-quality base paper is selected, usually made from long cellulose fibers to ensure mechanical strength. The paper is then treated with a resin solution through immersion, coating, or impregnation techniques. After impregnation, the paper is dried and cured under controlled temperature and pressure conditions, allowing the resin to polymerize and bond with the cellulose fibers. This results in a paper with enhanced rigidity, dimensional stability, and resistance to environmental factors such as moisture, chemicals, and heat.

Properties and Advantages

Impregnated paper offers several advantages over conventional paper. It exhibits high mechanical strength, allowing it to withstand compression, bending, and tearing under industrial conditions. Its chemical resistance makes it suitable for applications involving oils, solvents, and acids. Moisture resistance ensures that the paper maintains its structural integrity even in humid environments. Additionally, impregnated paper has excellent electrical insulating properties, making it ideal for use in electrical and electronic components such as laminates, insulation sheets, and circuit boards. The thermal stability of the material allows it to perform reliably at elevated temperatures without degradation.

Applications

Impregnated paper has a wide range of industrial applications due to its unique combination of strength, durability, and resistance properties. In the electrical industry, it is used to manufacture laminated boards, insulating materials, and transformer components. In mechanical applications, impregnated paper can serve as a spacer, gasket, or structural component where high mechanical stability is required. The decorative laminates industry also uses impregnated paper impregnated with melamine or phenolic resins to produce durable, high-quality surfaces for furniture, countertops, and panels. Additionally, impregnated paper is used in the packaging industry, especially for protective layers that require chemical and moisture resistance.

Types of Impregnated Paper

Impregnated paper can be classified based on the type of resin used and the intended application. Phenolic-impregnated paper is widely used for electrical insulation and industrial laminates due to its high heat resistance. Melamine-impregnated paper is preferred for decorative laminates and furniture surfaces because of its hardness, scratch resistance, and aesthetic finish. Epoxy-impregnated paper provides superior chemical resistance and is often used in printed circuit boards and high-performance insulation applications. The choice of resin and paper grade depends on the specific mechanical, thermal, and electrical requirements of the final product.

Conclusion

Impregnated paper is a versatile and high-performance material that combines the natural properties of cellulose with the enhanced strength, durability, and resistance provided by chemical resins. Its applications span multiple industries, including electrical, mechanical, decorative, and packaging sectors. By selecting the appropriate resin and paper grade, manufacturers can create customized solutions to meet specific industrial needs. As industries continue to demand materials that can withstand harsh environments and high operational stresses, impregnated paper remains a critical material for innovation and industrial reliability.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible