Impregnated Paper for Decorative, Industrial, and Insulation Applications

Impregnated paper is paper treated with resin to enhance strength, moisture resistance, durability, and stability for industrial and decorative uses.

Release time:

06 Jan,2026

Impregnated paper is a functional material produced by saturating base paper with resins or chemical solutions to significantly enhance its mechanical strength, durability, and resistance to moisture, heat, and wear. This process transforms ordinary paper into a high-performance substrate suitable for a wide range of decorative, industrial, and technical applications. Commonly used resins include phenolic, melamine, urea-formaldehyde, epoxy, and other thermosetting systems, selected according to the desired performance characteristics.

One of the most important properties of impregnated paper is its improved strength and dimensional stability. After impregnation and curing, the resin penetrates the fiber structure, bonding the fibers together and reducing porosity. This results in a material that resists tearing, cracking, and deformation under pressure or temperature changes. Such stability is essential in applications like high-pressure laminates, furniture panels, and flooring systems, where consistent performance and long service life are required.

Impregnated paper also exhibits excellent resistance to moisture and chemicals. The resin barrier limits water absorption and protects the paper from swelling or degradation in humid environments. This makes it ideal for use in kitchen and bathroom surfaces, laboratory furniture, and industrial settings where exposure to liquids, oils, or cleaning agents is common. Certain resin systems further enhance fire resistance, electrical insulation, and thermal stability, expanding the application range of impregnated paper.

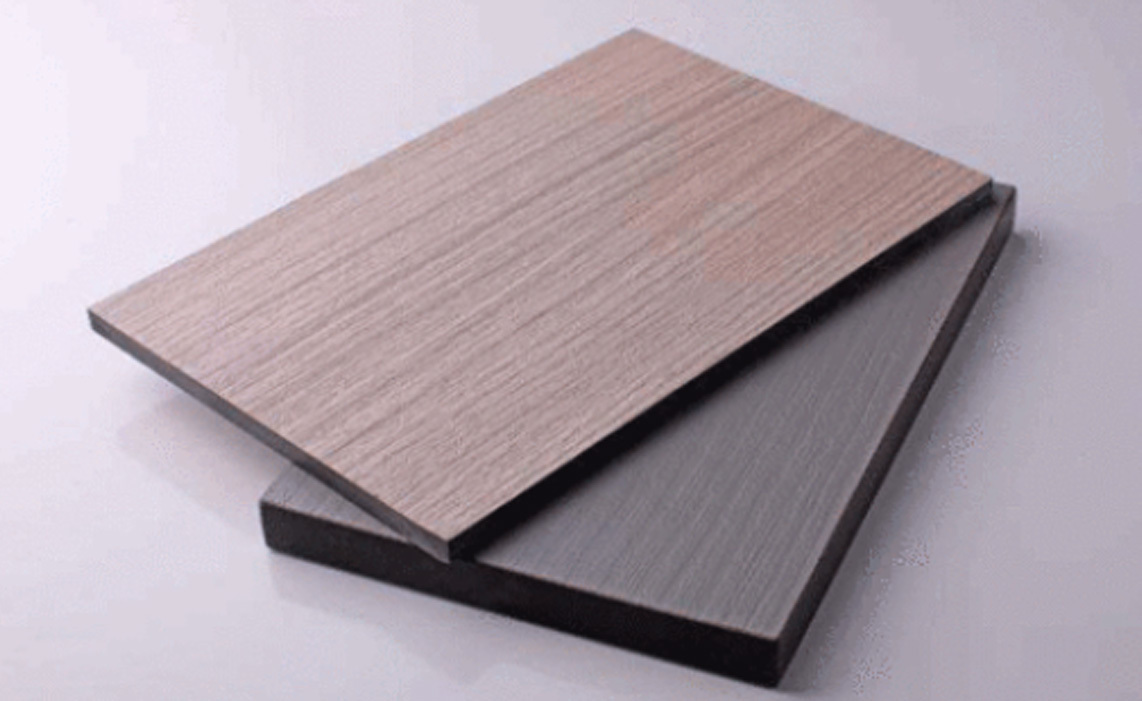

In decorative applications, impregnated paper plays a crucial role in surface finishing and design. Decor papers impregnated with melamine or similar resins are widely used as surface layers in laminated boards, countertops, wall panels, and flooring. These papers can carry printed patterns that replicate wood grain, stone, fabric, or abstract designs. During hot pressing, the impregnated paper fuses with substrates such as particleboard, MDF, or plywood, forming a hard, smooth, and visually appealing surface with excellent wear resistance.

From an industrial perspective, impregnated paper is used in electrical insulation, abrasive backings, filtration components, and packaging materials. Phenolic resin impregnated papers, for example, are commonly applied in electrical laminates, transformer insulation, and printed circuit board substrates due to their high mechanical strength and insulating properties. In abrasive products, impregnated paper provides a strong, flexible backing that withstands high stress during grinding or sanding operations.

Manufacturing impregnated paper involves precise control of resin content, viscosity, impregnation speed, drying temperature, and curing conditions. These parameters determine the final performance of the product, including flexibility, hardness, surface quality, and bonding strength. High-quality impregnated paper offers uniform resin distribution, consistent thickness, and reliable performance in downstream processing such as pressing, cutting, and bonding.

In terms of sustainability, modern impregnated paper production increasingly focuses on reducing emissions, improving resin efficiency, and using environmentally friendly formulations. Low-emission and formaldehyde-free resin systems are being developed to meet stricter environmental regulations and indoor air quality standards. Combined with the renewable nature of paper fibers, impregnated paper can be part of a more sustainable material solution when responsibly produced and recycled.

Overall, impregnated paper is a versatile and high-value material that bridges the gap between paper and engineered composites. Its enhanced physical, chemical, and decorative properties make it indispensable in furniture manufacturing, interior decoration, industrial processing, and electrical applications, providing reliable performance and design flexibility across numerous industries.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible