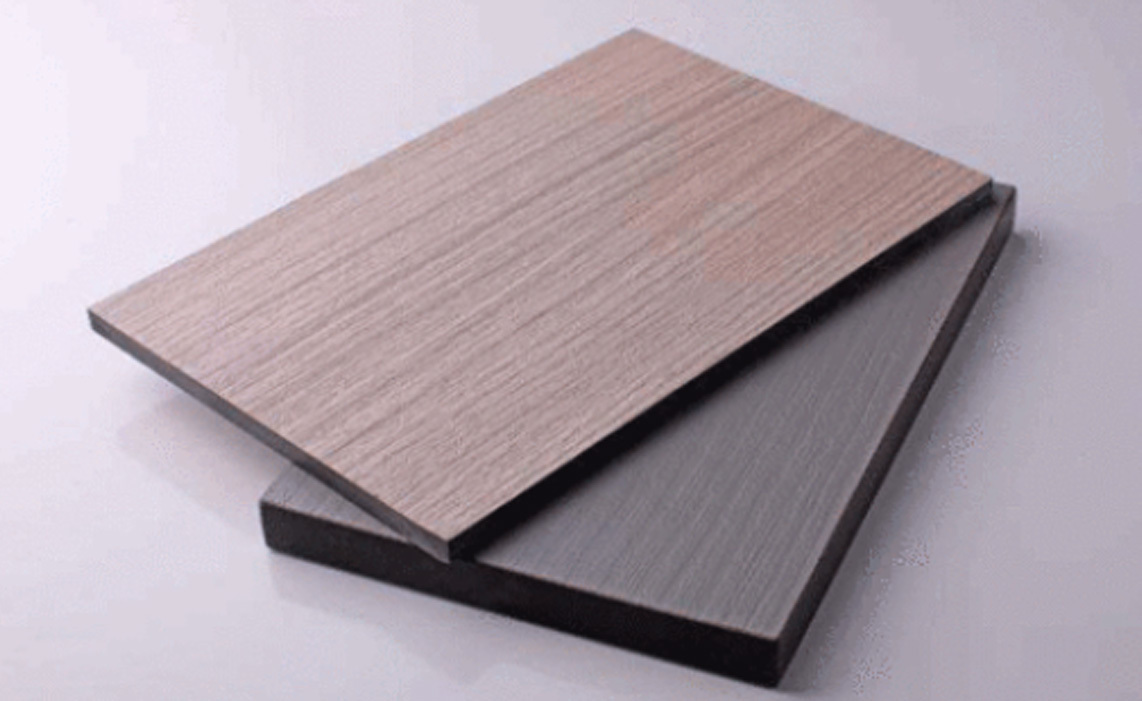

Laminated Panels – Durable and Versatile Surface Solutions

A laminated panel is made of bonded layers, offering strength, durability, and an attractive finish for furniture, walls, and interior applications.

Release time:

03 Dec,2025

Laminated panels are engineered materials composed of multiple layers bonded together to create a strong, stable, and visually appealing product. Typically, these panels consist of a core substrate made from medium-density fiberboard (MDF), particleboard, or plywood, overlaid with a decorative surface layer such as melamine, high-pressure laminate (HPL), or decorative paper impregnated with resins. The lamination process uses heat, pressure, and adhesives to ensure that the layers are firmly bonded, providing enhanced mechanical strength and long-lasting durability.

One of the primary advantages of laminated panels is their versatility in design and application. The surface layer can be manufactured in a wide variety of textures, colors, and patterns, ranging from realistic wood grains and stone effects to vibrant solid colors. This variety allows architects, interior designers, and furniture manufacturers to achieve the desired aesthetic without the cost and maintenance issues associated with natural materials. Laminated panels can replicate the look and feel of exotic woods, marble, or other premium surfaces, offering an affordable yet high-quality alternative.

Durability is another key feature of laminated panels. The lamination process creates a protective surface that resists scratches, stains, moisture, and impact. High-pressure laminates, in particular, are extremely resilient and suitable for high-traffic areas such as office furniture, kitchen countertops, retail displays, and public spaces. Low-pressure laminates, typically used for cabinetry or wall panels, offer sufficient protection while maintaining cost efficiency. Additionally, laminated panels are dimensionally stable, reducing the risk of warping or swelling when exposed to humidity changes.

Environmental and safety considerations have also driven innovation in laminated panel production. Many manufacturers now produce panels using formaldehyde-free adhesives or low-emission resins, ensuring compliance with international environmental standards and contributing to healthier indoor air quality. Some laminated panels are also recyclable or made from sustainable wood sources, aligning with eco-friendly building practices and green certification requirements.

The applications of laminated panels are extensive. In residential interiors, they are widely used for kitchen cabinets, wardrobes, furniture, wall cladding, and decorative partitions. In commercial spaces, laminated panels serve as office furniture, retail fixtures, wall panels, and countertops. Educational and healthcare facilities also benefit from laminated panels due to their ease of cleaning, hygiene, and durability. Specialized laminated panels with additional properties, such as fire resistance, antibacterial surfaces, or acoustic insulation, further expand their applicability.

Maintenance of laminated panels is straightforward, contributing to their popularity. Routine cleaning with a soft cloth and mild detergent is generally sufficient to maintain their appearance. Their resistance to scratches and stains reduces the need for frequent repairs or refinishing. In case of minor damage, localized repair kits or surface overlays can restore the panel’s look without full replacement, offering practical benefits for both homeowners and businesses.

The production of laminated panels involves precise engineering and quality control. The substrate must be properly conditioned to prevent moisture absorption, and adhesives must be evenly applied to ensure strong bonding. Advanced machinery ensures uniform heat and pressure during lamination, producing consistent thickness and surface finish. Modern production lines may also incorporate digital printing techniques, allowing for highly customized patterns and textures that meet specific design requirements.

In conclusion, laminated panels represent a perfect balance of aesthetics, durability, and functionality. They provide an efficient and cost-effective solution for a wide range of interior design and construction applications. With continuous advancements in materials, surface finishes, and sustainable production methods, laminated panels remain a reliable choice for modern residential, commercial, and public projects, offering long-lasting beauty and performance.

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible