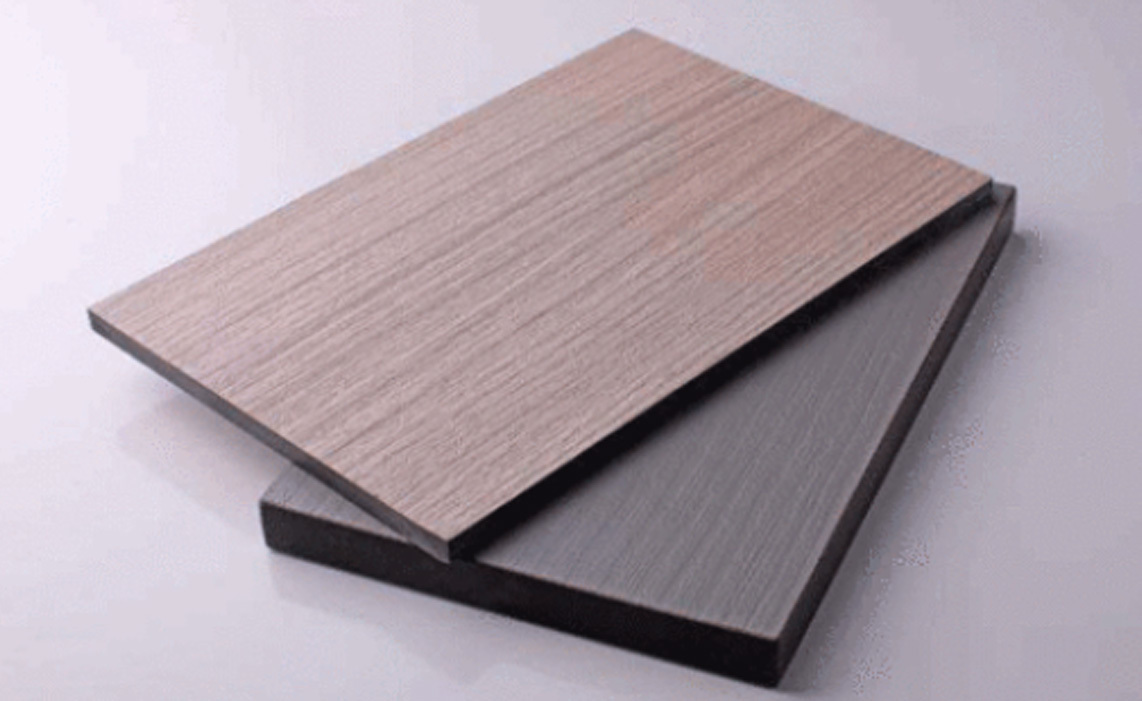

Construction process of wooden laminated board

Installing vertical keels on horizontal keels also requires adjusting according to the size and thickness of the wooden laminated board.

Release time:

15 Apr,2025

1. Clean the base surface

Before construction, it is necessary to clean the wall or other base surface, remove oil stains, dust, and loose substances to ensure that the base surface is flat, firm, and free of grease

2. Install horizontal keel

Install horizontal keels on the base surface, and the spacing between keels should be adjusted according to the size and thickness of the wooden laminated board, usually around 400mm

3. Install vertical keel

Installing vertical keels on horizontal keels also requires adjusting according to the size and thickness of the wooden laminated board

4. Install wooden laminated board

Place the wooden laminated board on the vertical keel, adjust the position, then use a drill to drill holes in the wooden laminated board, and then use screws to fix the wooden laminated board to the keel

5. Filling and repairing joints

Fill and seal the gaps between wooden laminated boards using wood paste boards and wooden strips. Then use a woodworking planer and sandpaper to trim and polish the surface of the wooden laminated board

6. Painting and care

Paint or perform other protective treatments on the surface of wooden laminated boards, and select appropriate coatings and processes for treatment according to specific requirements and design requirements

Latest Blog

22 Feb,2026

The Impact of Surface Materials on Acoustic Performance in Buildings

The Impact of Surface Materials on Acoustic Performance in Buildings When designing a building, architects and interior designers must consider various factors to achieve both aesthetic appeal and functionality. Among these factors, **acoustic performance** plays a crucial role in creating comfortable spaces. The choice of **surface materials** significantly impacts how sound behaves within a bu

Read More →21 Feb,2026

The Essential Guide to PVC Edge Banding: Enhancing Aesthetics and Durability in Interior Design

PVC edge banding has become an essential component in the world of construction and decorative materials, particularly for interior design applications. This versatile material is primarily used to cover the exposed edges of furniture, cabinetry, and other surfaces, providing not only a clean and professional appearance but also enhancing durability and protection against wear and tear. One of the

Read More →20 Feb,2026

The Role of Laminated Boards in Enhancing Acoustic Properties

The Role of Laminated Boards in Enhancing Acoustic Properties Table of Contents 1. Introduction to Laminated Boards 2. Understanding Acoustic Properties 3. How Laminated Boards Improve Acoustic Performance 3.1 Technical Advantages of Laminated Boards 3.2 Mechanisms of Sound Absorption 4. Applications of Laminated Boards i

Read More →Contact Us

Sales manager SUNNY LIU

+86 15751150508 (wechat、whatsapp)

E-mail: Sunny@devandecor.com

Add: NO.8 DONGHUAN RD,HENGLIN TOWN,WUJIN DISTRICT, CHANGZHOU ,JIANGSU,CHINA

Copyright © 2025 Changzhou Defan New Materials Co., Ltd. All rights reserved. www.300.cn SEO

Subscribe our newsletter

Welcome to leave us a message, we will reply to you as soon as possible